20/11/2020

|

why materials matter

Best of the yarn

Renowned for its textiles, the small Italian town of Prato is a veritable cashmere hub, hosting an elite circle of top-class manufacturers of cashmere yarn. At a time when growing volumes of questionable-quality cashmere…

more about our italian partner

20/01/2020

|

why materials matter

Another secret

Did you know that every cashmere item gets a wash before it’s dispatched? That’s because very few people would find unwashed cashmere attractive. Washing the fibres after they’ve been spun and knitted…

about the washer

14/01/2020

|

why materials matter

Magicans of Montale @ wor…

Transforming raw cashmere into yarn is a complex process that requires not only sophisticated machinery but also expert knowledge that few people command. The ideal combination of engineering and expertise…

more about the artists

06/12/2019

|

why materials matter

Arriving at the mill

When the raw cashmere comes off the train after 45 days en route from Asia to Italy, the big linen bales are opened and the contents visually inspected. As cashmere fibres are paid for by weight, the bales sometimes have stones, …

more about the way of the cashmere

24/11/2019

|

why materials matter

Detox-commitment

In March 2016, our yarn manufacturer signed up to the Detox project promoted by Greenpeace. Aware of the importance of eliminating hazardous substances from the production cycle, the company has chosen a greener route.

more about sustainable thinking

12/11/2019

|

why materials matter

Cold air, warm hair

The finest, softest and most durable cashmere fibres come from Mongolia, Inner Mongolia and Tibet. Why? For one thing there’s the dry and very cold climate, and for another the wide range of temperatures commonly…

more about hard conditions

06/10/2019

|

why materials matter

Sustainable yarns

Our decision to collaborate with our chosen yarn manufacturer in Prato was based on two key considerations: Firstly, nowhere have we encountered higher quality, and secondly, their commitment to sustainability makes them…

why we love sustainability

30/09/2019

|

why materials matter

Experience meets innovati…

Our yarn manufacturing partner originally came from the mechanical engineering sector where they developed and built machinery − and that same inventive spirit still pervades the company. So it comes as no surprise…

read more about perfectionist

06/08/2019

|

why materials matter

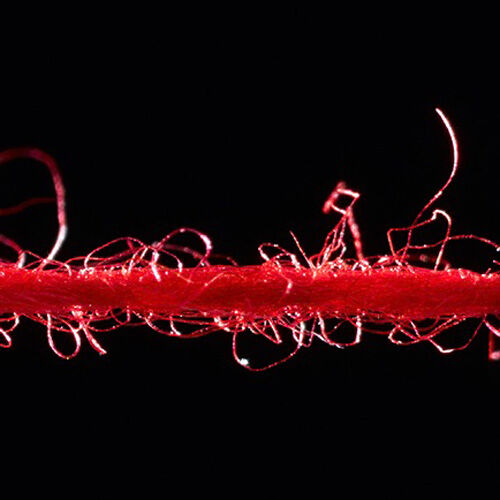

The buttertea yarn

2/28 cashmere represents a unique level of quality in which two strands or ‘plies’ are spun into a top-class yarn. Production of such high-quality yarn is restricted to a particularly exclusive circle of manufacturers, …

more about high end yarns